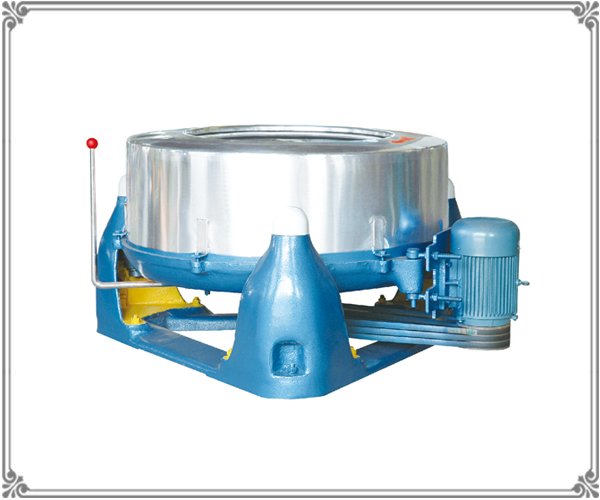

High degree of automation, safety

Touch-type programmable microcomputer automatic control has the advantages of high automation, safety and stability, strong anti-vibration and so on.

Strong corrosion resistance and durability

Rotary drum is made of excellent stainless steel with strong corrosion resistance and durability.

Strong vibration resistance

Using the international suspension structure of cylinder block, the original rigid shock design was replaced by the combined shock absorber structure of compression spring and hydraulic damper.

Stable, reliable and pollution-free phenomena

This machine is fully enclosed, front loading and unloading cloth, back water intake air pollution-free phenomenon. Special frequency conversion motor and famous brand frequency converter are used to make the machine run smoothly and reliably.